Engines

Upper Canada Railway Services is a quality supplier manufacturer and suppliers of EMD®, GE® and MAN (Roston) Locomotive Engine Components.

Our line of engine components covers EMD® 567,645, 710 and GE® 7FDL. These components includes:

- New 645 and 710 Engine Block

- Rebuilt and Utex567, 645 and 710 and 645 Engine Block

- New 710 Engine Oil Pan

- Cylinder Liner (Chrome and Laser Hardened)

- Cylinder Head

- Piston and Piston Crown

- Connecting Rod (Fork and Blade)

- Piston Carrier

- Piston Pin

- Piston Ring Sets

- Liner Studs

- Fuel Injectors

- Rocker Arms, Shafts and Bridges

- Line Assembly (Lube Oils and Fuel)

- Exhaust Valves

- Engine Bearings and Thrust Bearings

- Crankshafts

- Camshafts, Brackets and counter weights

- Damper Assemblies

- Gears and Gear Assemblies

- Engine Coupling Disk

- Over-speed Trip Linkage

- Engine Low Water Detectors

- Water Pumps

- Piston Cooling , Pressure and Scavenging Pump

- Lube Oil Strainer

- Lube Oil Manifold Assembly

- Lube oil filters and housings

- Exhaust Chambers, Expansion Joints and Turbo Screens

- Heat Shield and Silencers

- After Cooler Assemblies

All of our engine components are made to meet or exceeds the OEM specifications. Please brows the part numbers under categories listed on left pane pf this page. If you could not fond the part number that you are looking for, please do not hesitate to send us your inquiry and we are quite confident that could make or locate it for you.

Rebuilt / Overhaul Services:

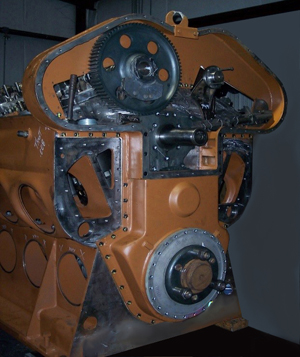

Upper Canada railway services could provide rebuild services for EMD® and GE® engine block, oil pan and complete engine assemblies. This procedure includes precise requalification of the engine block and identifying the problem areas, crack detection, welding and re-manufacturing process includes:

- Engine disassembly and thoroughly cleaning.

- Block Hydro test at 100 PSI with hot water (160F)and inspected for leaks and cracks

- Main caps are checked for cracks, stretching, and or defects. Replaced as necessary and line bored to new standards

- Head seat surfaces are checked and brought back to new standards once line bore is corrected

- Camshaft pads are checked for alignment and welded and /or milled to new specifications

- Exhaust deck and both end surfaces are milled flat and within OEM specifications

- Crab and main studs are inspected for crack and/or defects.

- Drain holes are drill for Overspeed Trip Housing, and replacing the bottom drains

- Air box cover seats are checked for any wear and/or dings and dents and repaired to flat surface for door seal

- All oil passages and drain lines are checked for cleanness

- All bolt holes are checked with gono go gauge. Any damaged threads are drilled out and replaced withlocking threading

- Block and pan is cleaned and primed with oil resistance crankcase sealant.

- New Lower Liner inserts are installed

- New engine bearings will be installed

- Crankshafts will be re-qualified or replaced with new if below permissible resurface tolerances.

- Power assemblies will be requalified with new piston rings and Viton seals. The cylinder heads will be requalified to OEM specifications or will be renewed. Pistons will be requalified or will be replaced. The piston pins and piston bearings inserts will be replaced.

- Gear Train will be requalified and re-installed. Gears will be replaced if necessary

- Re-qualify accessory drive Housing and install and gear lash will be adjusted.

- Repair / Requalify the water pumps and Install

- Requalify and install Oil Strainer

- Requalify front Crankshaft coupler with newrubber bushings and install on engine

- Install Governor drive

- Add water and oil piping

- Install EPD/Detector and all hosing with low water shut off valve

- Camshafts are installed with new bearings, torqued down and checked for free roll ( no tight spots) and proper thrust

- Overspeed trip housing is installed

- Governor and governor control arms are installed with new bearings

- Fuel block is added, New pressure check valves are added with new fuel filters and all piping