Traction Motors

Traction motors as proven statistically are the major contributors to locomotive maintenance cost. The railroads need them to stay in service for as long as reasonably possible to optimize the benefit from the investments of rolling stock and minimize the downtime of locomotives. Achievement of such important objective requires the utilization of OEM quality compliant traction motors and spare parts.

Upper Canada Railway Services is a reliable manufacturer and service provider for EMD, GE and Alstom and Siemens locomotive traction motors. Majority of the components are made to OEM print and according to OEM material specification and engineering test instructions. We strive to be the one-stop shop for all your locomotive traction component including supply complete new traction motors, new components, overhaul and complete rebuild and remanufacturing needs.

At Upper Canada Railway Services we know that the needs of each customer might be unique considering their geographical ambient, level of contamination, axle load, the degree of vibration, etc. Therefore we can also tailor the manufacturing processes and customize our products to meet the requirement of each customer.

To ensure that every traction motor adheres to the highestquality and reliability; all traction motors are thoroughly tested to test requirements that meets or exceeds the requirement as defined by customer. We utilize core loss testing, insulation test, bearing running test, over speed test, load test and hot burn test.

Manufacturing Capabilities

We are capable to manufacture complete brand new traction motors as listed below to OEM specification:

- EMD D29 / D31

- EMD D43

- EMD D77 / D78

- EMD D87 / D87B

- EMD D78BTR / D87BTR

- EMD D90 / D100

- GE 761 A15 to A23

- GE 752 AG/AH

- GE 752 RB3A / R6A

- EMD 1TB2622

- EMD 1TB2630

- Alstom SLO 2972101000

- Alstom SLO 2978301000

We are also capable of manufacturing all sub-components and spare parts for above mentioned traction motors. Our featured products includes but not limited to:

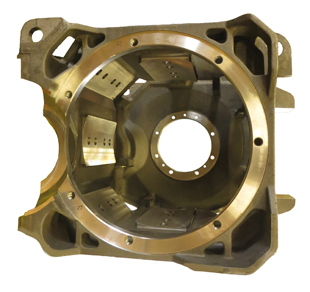

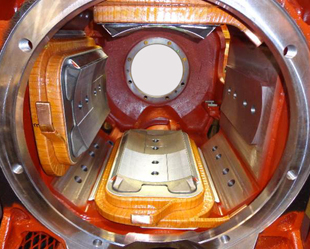

- Traction Motor Frame Assembly

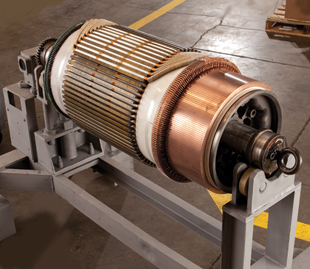

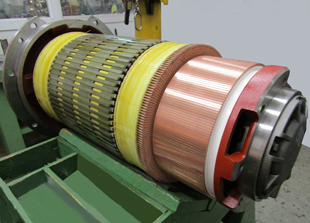

- Armature Assembly and Rotor Assembly

- Stator and Armature coils and rewind kits

- Armature spider assembly, coil supports and Rotor shafts

- Bearing Parts (Housings, Bearing Caps, Retainers, Seals, etc.)

- Lead Assemblies and internal connectors and bus bars

- Brush Holders

Re-manufacturing Capabilities

UCRS is virtually capable to repair any traction motors to its original specifications. These services includes:

- - DC armature rewind

- - Stator coils re-insulation (Silicone and Mica Technologies)

- - Stator Frame refurbishment (weld and machine)

- - AC Stator rewind

We are offering five level of traction motor rebuilt to suit any customer’s need or budget as follows:

-

TIER 1:

- - Disassemble and Wash

- - Test and Requalify

- - Replace faulty parts

-

TIER 2:

- - TIER 1

- - New Bearings

-

TIER 3:

- - TIER 2

- - Rewind the Armature

-

TIER 4:

- - TIER 2

- - Rewind Stator

-

TIER 5:

- - TIER 2

- - Rewind Armature

- - Rewind Stator

UCRS is capable to modify the existing traction motors to the latest design and modification by OEM to improve the performance and longevity of traction motors.

The most recommended modifications by industry that could be carried out by UCRS are:

- D77 Armature to D78

(Transposed Armature Coils) - D78 and D87 Armatures to D100

(Ventilated Coil Supports, modified Commutator, Modified Armature Coil Insulation) - D29 Traction Motor to D31 Traction Motor

(Modified Armature Coils) - D78BTR /D87BTR to D78BTR / D87BTR

D78BTR /D87BTR to D78BTR / D87BTR

We would also capable to modify the traction motors to special requirement of the customers.