Filters

UCRS is capable of manufacturing and supplying a wide variety of Air, Fuel and Oil filters housings, strainers, and inertial air filters. We are also capable of supplying a wide range of air, lube and fuel filter elements that assure the safe operation of locomotives. This will result in higher durability and longevity of the locomotive components and a reduction in downtime operation. Maintaining the filtration systems of locomotives is critical and vital to the operational life of different systems of the locomotive, and therefore, the utilization of high-quality elements is emphasized throughout all maintenance instruction of the locomotives.

Please view our filter parts listing. If you do not see the number, you are looking for, please contact our sales team and we are confident we can serve you with your needs.

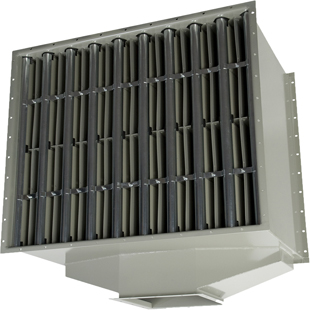

Inertial Air Filters

Inertial separators are highly efficient as a primary air filtration device or as a pre-cleaner for high efficiency secondary filters.

The newer generation of inertial air filters are self-cleaning and do not require regular replacement of elements. These inertial filters are recommended where dust concentrations are extreme or where service work must be minimized. The Centrifugal force resulted from the unique impeller shape of the filter tubes propels the aspirated engine air, creating a spinning motion separates the dust from the intake airflow. The separated dust particulate is then bled away from the airstream by means of a scavenge fan, making the filter a self-cleaning system that does not require replacing elements.

The older generation of inertial filters are proven to be one of the most effective high volume air cleaners for use in pre-cleaning, single and multi-stage filtering systems. It has been demonstrated over many years of application that these inertial separators will perform efficiently in a wide variety of operating conditions, at all volumes of air flow. These filters can remove 10% more airborne contaminants than any competitive unit, resulting in a much cleaner air compartment, generator, traction motor and blower. This inertial separator is designed to provide long term, trouble-free service under the most difficult conditions.

Inertial filters are environmentally friendly, and a sustainable product, as they self-clean and do not require regular replacement associated with typical throw-away barrier filters. The application of inertial filters on locomotives significantly reduces the consumption of air filter cartridges and will enhance the longevity of locomotive components